The most crucial AXES of a press brake are X, Y, Z, and R. These axes can be managed either numerically or manually through the operator, dependant upon the particular press brake configuration and capabilities.

Below at our shop, we just take pride in manipulating metal to satisfy the visions of our clientele, making certain Just about every bend serves the two functionality and sort.

1. Hydraulic Press Brakes: Use hydraulic cylinders for power generation, providing large tonnage capabilities and consistent pressure all through the stroke.

The pedal switch in the press brake plays an important role in managing the vertical motion with the upper beam or ram, which retains the very best punch.

Electrician reconnected the unit at proprietor's shop. The machine hasn't been utilized for manufacturing since that point. Proprietor has no motive to consider the unit isn't going to get the job done mainly because it must. Machine is available for inspection. Unit doesn't have hydraulic fluid; nonetheless, controls is usually turned on and CNC functions analyzed. If likely customer wants to refill with hydraulic fluid at their cost to completely exam machine, that is suitable.

Vernier calipers, While not precise to press brake operations, are indispensable for measuring content thickness, flange lengths, and also other important Proportions. Modern day digital calipers offer substantial precision and will evaluate equally inner and external Proportions with ease.

HYDRAULIC CYLINDERS (in hydraulic press brakes) where a piston driven by a fluid (oil) below pressure from the pump moves the higher beam (or, almost never, the bench), generating the mandatory power for bending.

Bend allowance is really a manufacturing phrase that refers back to the allocation presented to support sheet metal’s stretch and bending.

The oil seal ring is a vital component in hydraulic press brake machines, actively playing a vital position in retaining system integrity and operational performance.

Faster generation with tighter tolerances and much better precision technological know-how is just achievable if the material inserted in to the machine is straight and degree and exactly ready for that processing that follows.

Given that the workpiece is formed, it may well lift or interfere While using the decreased portion of a set gauge, potentially compromising accuracy or harmful the part.

The punch can be a reliable substance which is decreased down onto the metal. For the reason that pressing action of the punch on to the metal as well as die are what leads to the metal to bend, equally designs has to be accurately suited for the bending work.

You'll be able to relate bottoming with the air bending system, but the difference would be that the punch presses the sheet into the die till it entirely contacts the cavity surface area. This system solves the springback hazard defect linked Visit this page to the air system.

Sheet metal bending might sound like just An additional action while in the manufacturing course of action, but it surely’s an art form that mixes know-how, physics, and craftsmanship.

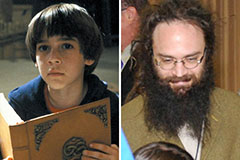

Barret Oliver Then & Now!

Barret Oliver Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!